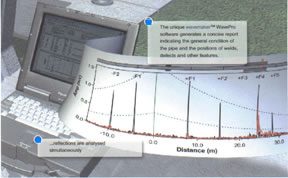

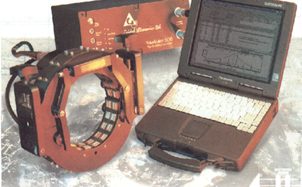

The "Wavemaker"

Engineering & Inspections International is pleased to announce the second generation of the guided wave ultrasonic technology named the “Wavemaker”. This technology opens a new era in global inspections capable of characterizing long runs of pipe from a single inspection point.

The Wavemaker system has been redesigned, lighter in weight, and more compact than prior systems along with an upgraded software and programmed in C++. It is the new low frequency ultrasonic tool that utilizes both torsional and compressional waves that can detect corrosion in pipe up to 200 feet in either direction from a single inspection point.

Applications

- Soil to Air Interfaces

- Road Crossings / River Crossings

- Fueling Facilities / Tank Farms

- Pipeline Systems located in Harbors

- Pipelines Buried under Pavement

- Municipal / Buried Pipeline Systems

- Insulated Lines / Coated Piping

- Wall / Bulkhead Penetrations

- Rapid Screening of Multiple Lines

- Corrosion Under Insulation

- In Plant – In Service Systems

- High Overhead Lines

- Applications are Endless

Advantages

- Excavating of Locations

- Insulation Removal and Installation

- Erecting / Disassembly of Scaffolding

- Pipeline / Systems Down Time

- Independent of Fluid in Pipe

- Ability to Detect Severe Axial Cracks

- Ability to Test Nearer to Large Features

- Does not Require Launchers of Receivers

- Experienced Operators and Analyst

- Immediate Results on a Daily Basis